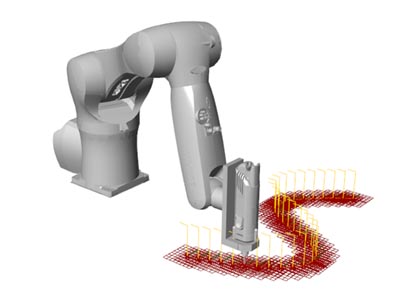

Simple Drawing/Engraving

Requirements: Rhinoceros 5, Grasshopper 0.9.0076, KUKA|prc V2

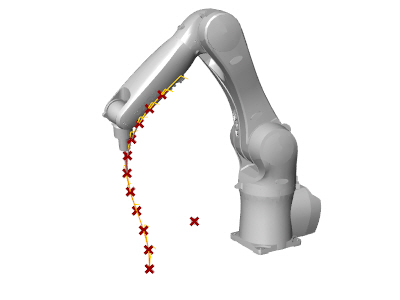

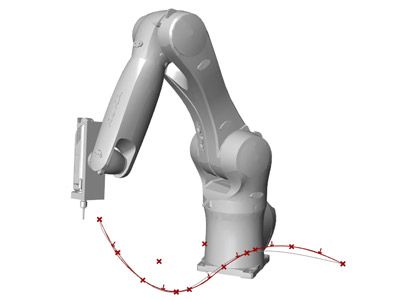

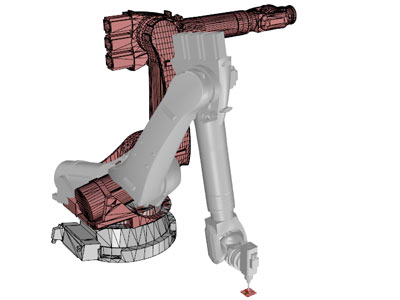

A simple example on how to have the tool follow a toolpath, e.g. for drawing or engraving.

Requirements: Rhinoceros 5, Grasshopper 0.9.0076, KUKA|prc V2

A simple example on how to have the tool follow a toolpath, e.g. for drawing or engraving.