Hello,

You are correct about the base and tool - you first have to calibrate the tool and base on the robot and then use the same number that was set at the robot inside KUKA|prc. The XYZABC values in KUKA|prc are only used for the simulation.

There is a particular reason for that - let's assume that a milling tool breaks and you have to put in a new one. If the values were hard-coded, you would have to go back into KUKA|prc and change them there again. As only the ID is referenced, you just have to save the new tool with the same tool-number.

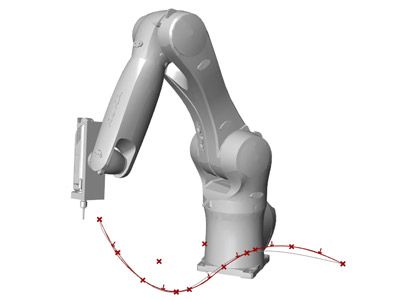

By default we're using X as the tool axis in the tool definition - as in the KUKA manuals. If you go into the settings of the Custom Tool component, there is an illustration. However, you can use the Z-axis as well, there is an option in the KUKA|prc settings for it (though I'm not 100% sure if it's already available in the trial version).

If you're using planes as the input for movements, the planes' positive Z-axis will be the tool axis.

...so to sum things up: You assumed correctly!

Best,

Johannes

You are correct about the base and tool - you first have to calibrate the tool and base on the robot and then use the same number that was set at the robot inside KUKA|prc. The XYZABC values in KUKA|prc are only used for the simulation.

There is a particular reason for that - let's assume that a milling tool breaks and you have to put in a new one. If the values were hard-coded, you would have to go back into KUKA|prc and change them there again. As only the ID is referenced, you just have to save the new tool with the same tool-number.

By default we're using X as the tool axis in the tool definition - as in the KUKA manuals. If you go into the settings of the Custom Tool component, there is an illustration. However, you can use the Z-axis as well, there is an option in the KUKA|prc settings for it (though I'm not 100% sure if it's already available in the trial version).

If you're using planes as the input for movements, the planes' positive Z-axis will be the tool axis.

...so to sum things up: You assumed correctly!

Best,

Johannes